|

|

|

|

| |

RWE Goldenbergwerk Fact Sheet: Carbon Dioxide Capture and Storage Project |

|

|

|

Company/Alliance: BASF, RWE Power and the Linde Group

Location: Hürth, near Cologne, Germany

Feedstock: Coal (lignite)

Size: 450 MW Gross, 360 MW Net: 2.3 MT/Yr of CO2

Capture Technology: IGCC, Pre-combustion

CO2 Fate: Sequestration in saline reservoir

Timing: Power Plant - Phase 1: Project development (2006-2008); Phase 2: Engineering and approval procedure (2008-2010); Phase 3: Construction and commercial operation Project is currently on hold

CO2 Storage - Phase 1: Selection of storage site (2006-2008); Phase 2: Evaluation of storage site (2008-2010); Phase 3: construction of storage facility (2011-2014); CO2 storage (2020) |

|

| Motivation/Economics: Total cost is €2 billion (US$2.577 billion). RWE has already committed €1 billion (US $1.3 billion) with €800 million (US$ 1.1 billion) for the power plant and €200 million (US$ 280 million) for the pipeline and CO2 storage operations. |

|

Comments: The implementation of the IGCC-CCS project requires the German Carbon Storage Law (KSpG) be passed. Without this legal framework exploration for suitable CCS storage sites cannot be done. Without the storage site located, the rest of the infrastructure cannot be planned and built. Therefore RWE has decided to defer the first steps necessary to implement the IGCC project in Hürth and halt engineering activities for the power plant.

RWE Power had been working with RWE Dea to use their knowledge of the exploration of oil and gas for storing natural gas to find suitable geological formations on or offshore. RWE Power is making €2 billion (US$ 2.7 billion) available for its climate protection program until 2014, including spending money on renewable energy and CO2 reduction in developing countries. RWE Dea had planed to investigate suitable storage locations in Schleswig-Holstein. |

|

Project Link: RWE IGCC project website |

|

IGCC with CCS technology viable on an industrial scale

RWE systematically promoted the developments required to implement the climate-friendly coal-fired power plant including carbon capture and storage (CCS). Between 2006 and 2010 extensive engineering work was performed for a CCS power plant on the basis of the IGCC technology (Integrated Gasification Combined Cycle) at the Hürth location. The IGCC technology can already be implemented on an industrial scale today.This technology is by no means new to RWE Power. It was already being researched in depth by the company in the 1980s and 1990s. At that time, efficiency improvements were to the fore. Today, we are developing the IGCC technology primarily in view of the requirements of sustainable climate protection since, unlike other processes, carbon capture is comparatively easy using the IGCC process, so that the effects of carbon capture and storage on efficiency can be kept relatively low. |

|

|

|

|

|

IGCC with CCS technology viable on an industrial scale |

|

|

RWE systematically promoted the developments required to implement the climate-friendly coal-fired power plant including carbon capture and storage (CCS). Between 2006 and 2010 extensive engineering work was performed for a CCS power plant on the basis of the IGCC technology (Integrated Gasification Combined Cycle) at the Hürth location. The IGCC technology can already be implemented on an industrial scale today.This technology is by no means new to RWE Power. It was already being researched in depth by the company in the 1980s and 1990s. At that time, efficiency improvements were to the fore. Today, we are developing the IGCC technology primarily in view of the requirements of sustainable climate protection since, unlike other processes, carbon capture is comparatively easy using the IGCC process, so that the effects of carbon capture and storage on efficiency can be kept relatively low |

|

|

Coal gasification including carbon capture

|

|

|

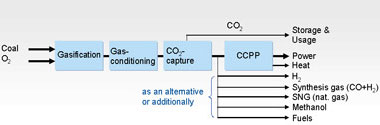

In our IGCC process, the gasification of lignite is combined with carbon capture, and electricity is generated in downstream gas and steam turbines. To this end, coal is not burned in a conventional steam power plant, but first converted into a combustible crude gas in a gasifier at high temperatures and a pressure of approximately 35 bar. The gas, which consists mainly of carbon monoxide (CO) and hydrogen (H2), is purified and the carbon monoxide converted into CO2 and more H2 in the CO shift. Following desulphurization, the CO2 is captured, compressed and transported to a storage site. |

|

The remaining hydrogen is then burned in a gas turbine driving a generator to produce electricity. The hot flue gases, consisting in the main of atmospheric nitrogen and pure water vapour, are used to generate steam. This steam drives a steam turbine and a second generator to produce electricity. Since the electricity is being produced using a particularly effective combination of gas and steam turbines, this power plant principle is referred to as a “combined-cycle power plant”. |

|

|

|

|

Application and product flexibility

|

|

|

The technology employed in the IGCC-CCS project in principle offers the opportunity to produce electricity in a flexible fashion. This is important especially in light of the increasing feed-in of renewable energy sources, such as wind and solar power, into the electricity grid. The energy yield from renewables, the predictability of which is limited, could be supplemented in a sensible manner by employing the virtually zero-CO2 IGCC-CCS technology.

The synthesis gas produced during the process may basically be used either energetically, as in the IGCC power plant described above, or materially to produce various chemical products or fuels, for instance hydrogen to be used as a fuel in the transport sector. Further material use requires additional conversion steps. Methanol and synthetic natural gas (SNG), among others, but also motor fuels such as diesel and petrol can be produced from synthesis gas using well-known processes that are commercially available today. The wide variety of possible uses is shown in the diagram below. |

| |

|

This flexibility on the product side for future applications is one more important motivation for the use of coal gasification. |

|

|

|

|

|

|

|

|